The earliest memory I have of seeing an object being 3d printed was on the 3D Printing Nerd Youtube channel. I don’t remember the video that got me hooked but it has been a topic of heavy interest for a long time. Specifically FDM printing, though all methods are neat.

My partner and I got our first printer in November of 2020, a Creality Ender 3 V2. A great starter, pre assembled printer that we had a lot of fun with.

We printed some house hold items like bag clips and pen holders. Even a gift or two. Then came the rabbit hole I like to call, 3d printing as a hobby.

The reason I could justify the small but not insignificant cost of a printer during 2020 was that “there were DIY upgrades to make it better”. In hindsight, this was a much larger undertaking than I was expecting being a complete hands-on novice of the space. Though just a few months later in January I started down the road I would not be able to successfully conquer.

A mod that brought hot swapping 3d printer nozzles came across my youtube. For context, this meant that it was easy to change out the hotend for different features or capabilities. A process that would normally take many many hours, would take a few seconds. On top of being awesome, it was compatible with my entry level printer and I was all over it! It was also from a company known for bringing quality mods to my entry level brand of printer as well, so the fact it was a kickstarter did not bother me much.

I got the kit and started ripping apart my brand new printer. My partner was not thrilled by this as you can imagine. Even more so when we found out that cutting some wires was necessary and hard to fix if done wrong. All was good though, I got the hotend shoe mounted to the machine and things were testing great with my multimeter. Then the horrible part of the story begins.

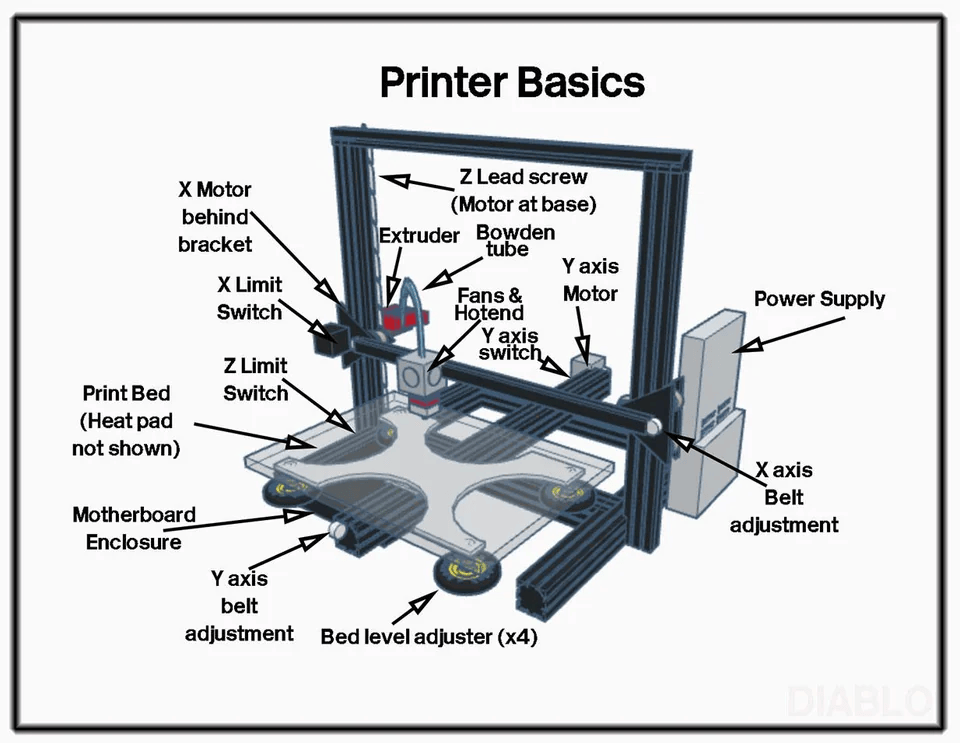

There was a piece in the kit, specific to my printer that was missing. Because the shape of the hotend shoe had changed, it was no longer hitting the x axis gantry limit switch anymore. This tells the printer motor to stop moving the printer in a specific direction, gathering it’s britches in 3d space, without that the printer could not operate. Of course in the printer community the suggestion was to print a piece to get the job done. I unfortunately no longer had an operational printer to do this on. To finish out the saga, the company went out of business because of a hurricane in Florida and so I wasn’t able to get the piece I needed or the digital model to print it. And this is where I realized the difference between printing with a 3d printer and having 3d printing as a hobby.

I fell in love with the idea of being able to create cool and useful things myself, at home. I was not looking for another hobby to dive into and embrace. My love for tech and electronics bested me here with this first printer.

For the time since, I have continued to watch content around the 3d printing space and marvel at the continued innovations. Most recently input shaping.

I am hopping back in as my partner and I decided to save for an appliance level printer, one that doesn’t need “DIY upgrades to make it better”. After the latest debacle with what I thought to be the industry leader, we have chosen the Core One from tried and true Prusa Reasearch. Our focus is for it to be a home appliance, meaning I have sworn to not DIY anything. Though a great thing I learned about Prusa, they make upgrade kits and mods for the printers 1st party! Meaning upgrades will come over time, even if a bit behind the community. Certainly something I can get behind. Also, they use standard parts, focus on right to repair and open-source.

Hopefully I can write more about getting back into printing once we have the printer in hand. ✌🏻

Leave a comment